Interested in how we engineer supply chains? Take a tour through lean buy’s comprehensive supply chain engineering process and explore in detail what has made us our clients' preferred sourcing partner.

-

1

Product Analysis

-

Product Definition

2 -

3

Partner Screening

-

Product Sample

4 -

5

Logistics Execution

-

Order Tracking

6

Bilateral Non-Disclosure Agreement

Before the exchange of any technical or commercial information takes place, we take it as a mandatory prerequisite to sign off a bilateral non-disclosure agreement with our clients. We take data privacy seriously and commit to our responsibility of keeping our client’s data safe and secure from access by third parties at all times, without exception.

Read MoreFit-Gap Workshops

Once an inquiry has been submitted to lean buy, our engineers start to dig into the technical supporting documentation in order to gain a profound understanding of the nature and functioning of the requested product. Depending on the complexity of the product, we apply brief fit-gap workshops which are intended to close the potential gap between our client’s expectations and our engineers' understanding. We, as a matter of course, run those fit-gap workshops via efficient video conferencing sessions (max 45 minutes) and come prepared with a list of concrete open questions.

Read MoreRegulatory Requirements

The EU blue guide, in particular, stipulates a whole range of requirements for various product categories and requires valid declarations of conformities for placing products onto the European market (e.g. CE marking). Our technical team of experts make sure to address and consider those critical regulations during the analysis process and thereby ensure a smooth, compliant import of your goods.

Read More

Technical Specifications

Durability, heat resistance, surface finishing, regulation conformity (ISO / DIN EN / CE) and coloring are just a few of the variables we query during the product specification process. All of this information is backed up by technical drawings and minutes which are transmitted securely encrypted and stored safely on our platform for mutual viewing.

Read MoreCommercial Specifications

lean buy understands proper results to be the right combination of quality and price. It therefore comes as a matter of course for our fellows to obtain and record all commercial conditions way before the first order. Starting from basic company data, such as VAT IDs, through incoterm clauses all the way to the accounting of import tax and customs duties we document all cost drivers transparently and in detail.

Read MoreLogistics Specifications

Even the perfect product at a competitive price is not marketable if it is delivered incomplete, damaged, late or mixed with other shipments. Logistics quality is crucial! That's why we discuss and anticipate unloading procedures, warehouse opening hours, vehicle and special delivery requirements (e.g. just-in-time or just-in-sequence) as part of our pre-sales-process in advance to the first delivery.

Read MoreRequirement and Functional Specifications

In preparation for the tendering of the production order to our contract manufacturers, we transfer all technical data into a formal supply agreement which reflects the consensus of the requirement and functional specifications. This document reflects the production requirements in a clear and structured manner and, thus, forms the basis for the continuous and correct execution of production processes needed for meeting expected quality levels.

Read More

Partner Identification

On account of our long-standing and well-developed partner network, lean buy can choose to tender the required production to a range of preferred contract manufacturers whom we are convinced will process the production order to our client’s full satisfaction. Besides our existing relationships with selected production and logistics partners, we regularly expand our network by using professional channels, like the International Chamber of Commerce, or, alternatively, by means of recommendations and contacts of our local ambassadors in the production countries.

Read MorePartner Selection

Over the period of collaboration, we have compiled and recorded the specific strengths and weaknesses of our partners. Our structured scoring model records our partners strengths and weaknesses in a comprehensive database with various criteria dimensions. We select the preferred partner by using an objective scoring model which matches our clients' success factors with our partners' strengths. Finding the perfect match between our clients' requirements and the most suitable contract manufacturer by the support of our professional scoring model ensures the highest level of client satisfaction.

Read MoreMother Tongue Communication

lean buy lowers the probability of language-induced production risks by assigning purchase coordinators and local ambassadors to ensure a full and correct understanding of the production requirements in the native language of the contract manufacturers. In the event of very complex and large-scale production orders, lean buy issues a proper translated version of the technical requirements to its partners.

Read More

Reference Sampling

Even though the product requirements have been neatly documented in the Supply Agreement with our contract manufacturer, there is no better way to manage expectations than to present a physical workpiece to our clients and to have it officially signed off prior to mass production.

Read MoreQuality Assurance Agreement

Given that the provided workpiece has been inspected and approved by our clients, the supply agreement towards our production partners and the quality assurance agreement with our clients get supplemented by detailed and illustrated documentation of the workpiece in order to make it a true reference sample for future deliveries. The Quality Assurance Agreement is signed off by all parties and becomes accessible thereafter via the client portal.

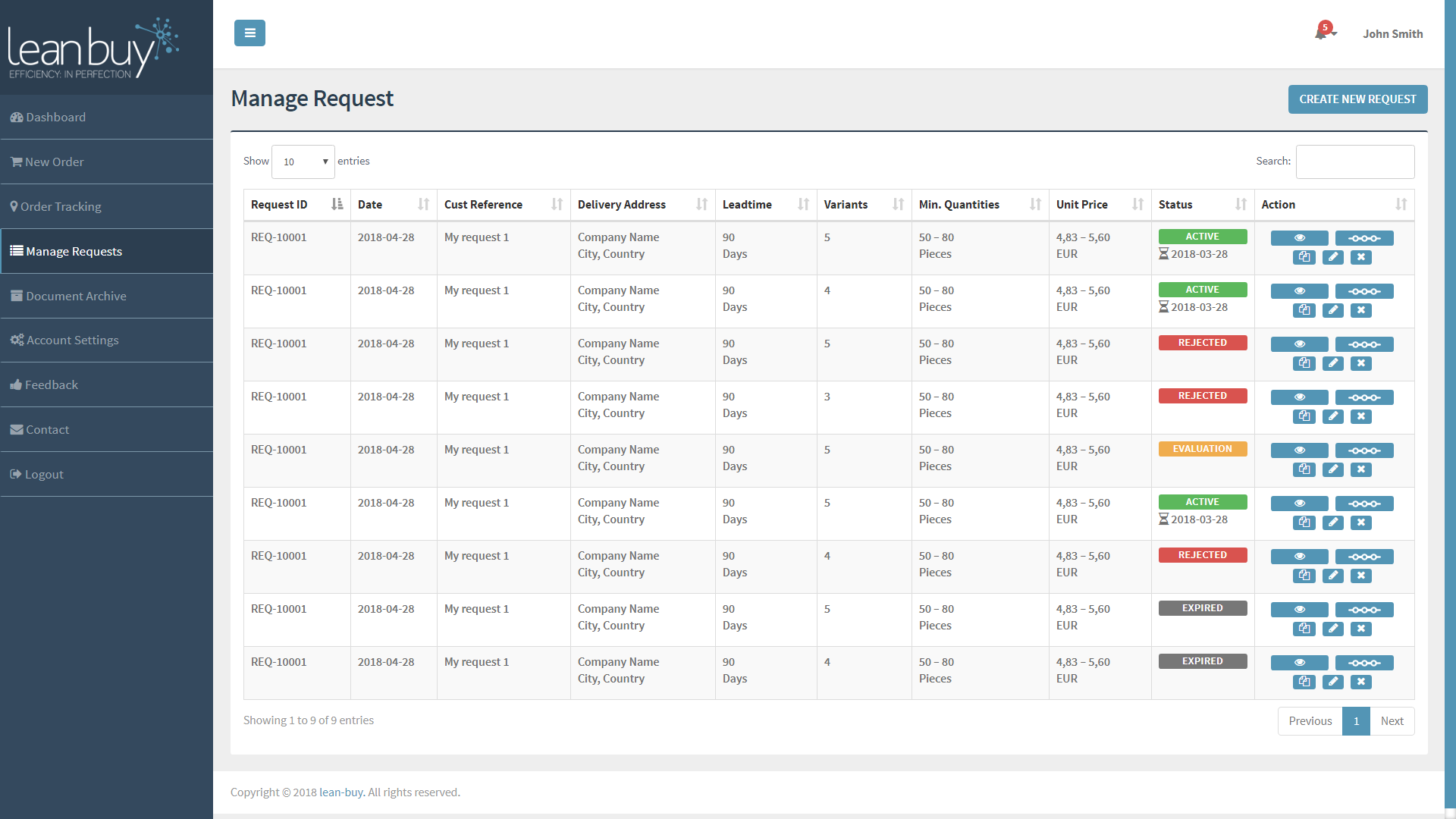

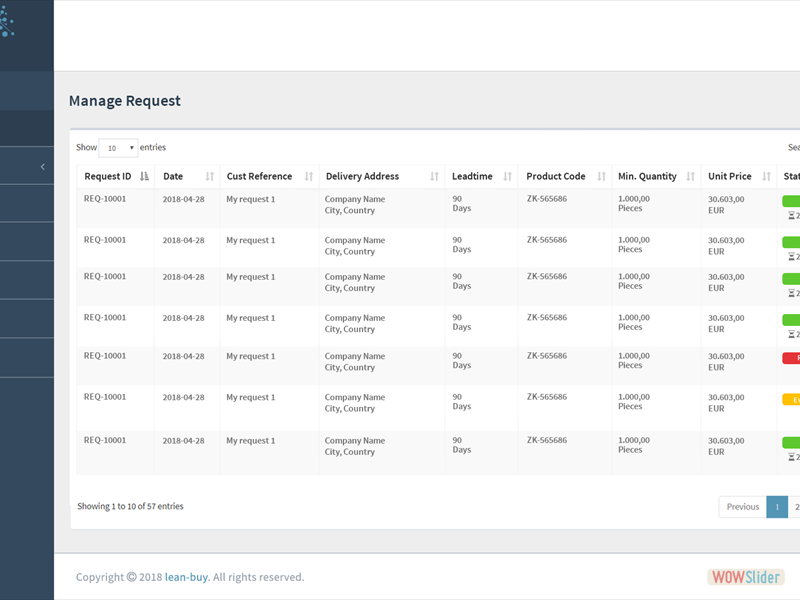

Read MoreInquiry Status

The activation of an inquiry to a framework agreement, against which regular orders can be placed, happens subsequent to the successful approval of the reference sample by our clients. Subsequently the process allows for straight forward 1-click order placements against the readymade agreement which contains all the agreed technical, commercial and logistics conditions.

Read More

Order Placement

By submitting an order via phone, an application interface or via the client portal, a multitude of supply chain planning and execution processes are triggered at lean buy. For our clients, however, it’s just about choosing an active framework agreement (inquiry) from the list, selecting the product variant, entering the requested quantities and a desired arrival date. It feels just like a hassle-free purchase from a webshop.

Read MoreContinuous Supply Chain Planning

At lean buy we constantly simulate the utilization of our production and freight capacities. Any new order is entrusted into the appropriate planning streams, based on the order-specific production effort required and the weight/volume proportions. Our professional supply chain planning allows for a reliable and cost-efficient delivery of the product within the given parameters.

Depending on the product’s sensitivity and the shipping method foreseen, we ensure the safe and adequate packaging necessary to make your goods not only fit for travelling overseas, but also for the last mile distribution and any subsequent handling.

Freight Mix

Different orders created for the categories of production materials, consumables and promotional items result in voluminous and dense shipments, which, if intelligently consolidated, not only allow for leveraging economies of scale, but also drive optimal capacity and freight tariff utilization across all modes of transport.

Read MoreSpecial Delivery Requirements

Apart from the administrative applications, licenses and customs reporting (incl. Intrastat), lean buy also caters for industry specific distribution requirements. We are capable of delivering advanced logistics concepts, such as just-in-time, just-in-sequence or cold chain deliveries for our trusted client bases from the automotive, industrial and pharmaceutical sectors.

Read More

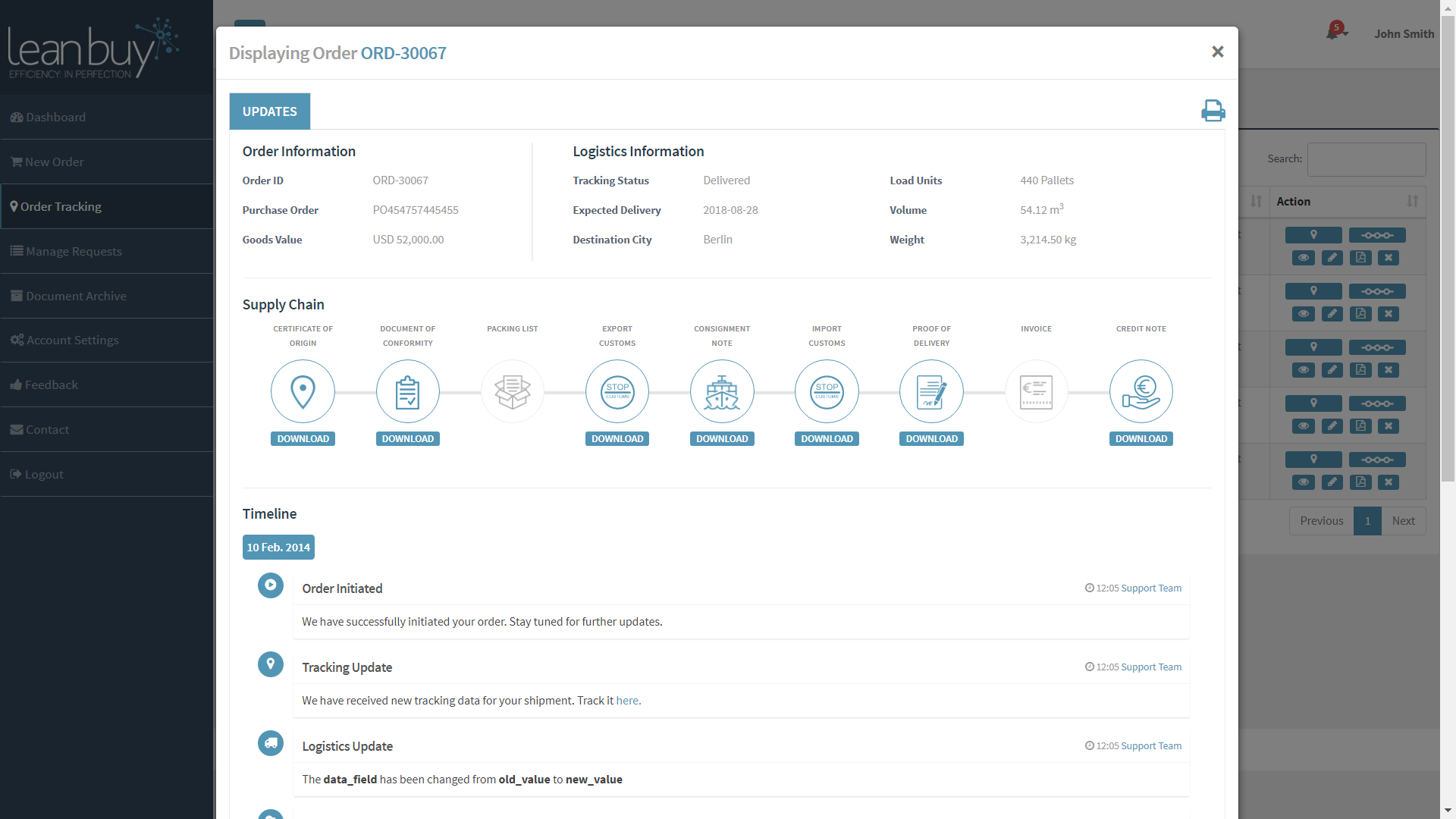

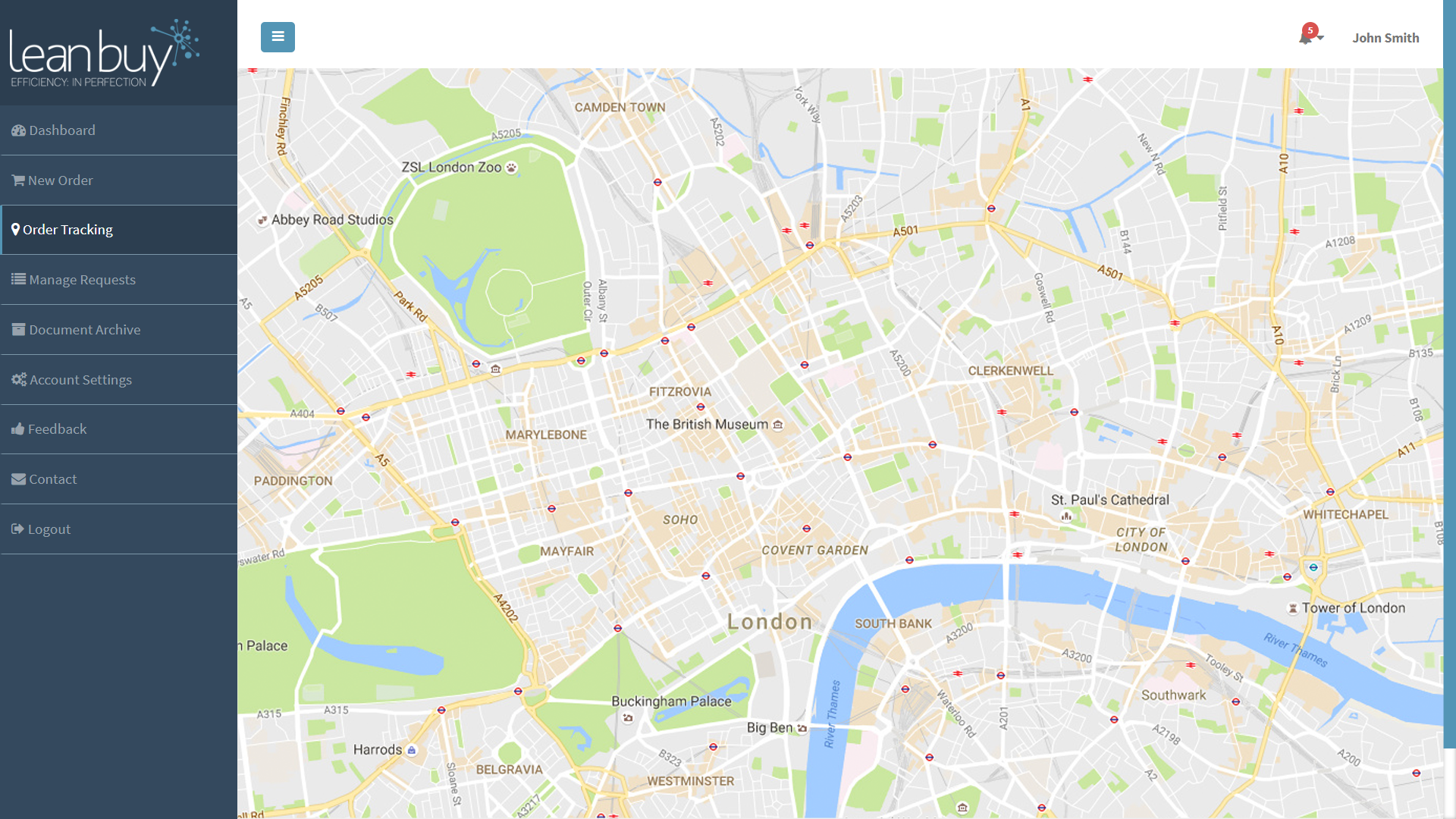

GPS-featured Tracking

We have integrated our tracking system with the majority of freight forwarders as well as the Universal Automatic Identification System (UAIS), which allows our clients to track their shipments using the most recently received GPS coordinates on Google Maps. Further delivery data such as the pre-advised delivery address, the expected delivery date, delivery milestones and any (unlikely) unforeseen events are directly accessible to our clients from the client portal via the order tracking page.

Read MoreOrder History

Any changes to inquiries and orders are automatically and neatly documented in the corresponding order timelines, which can be accessed via the client portal. All essential information is gathered in one place, which keeps all interested stakeholders updated about the progress of the respective transaction.

Read MoreDocument Provision

There will, naturally, always be a multitude of documents associated with the delivery of an international shipment. All different document types, such as certificates of origin, long-term supplier declarations, delivery proofs, invoices, credit notes and many others, are uploaded into the respective order history to enable for an immediate and hassle-free download on demand.

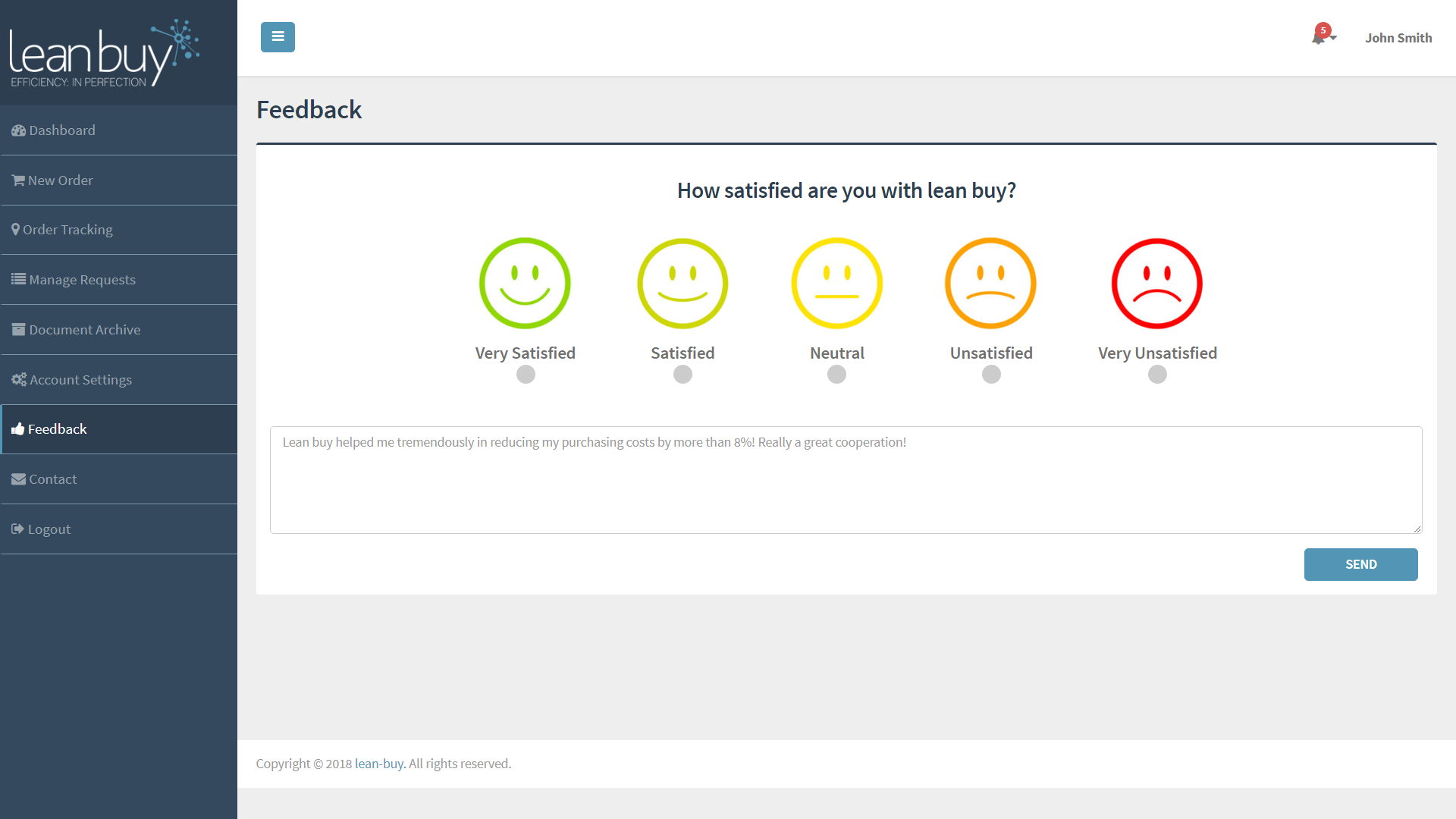

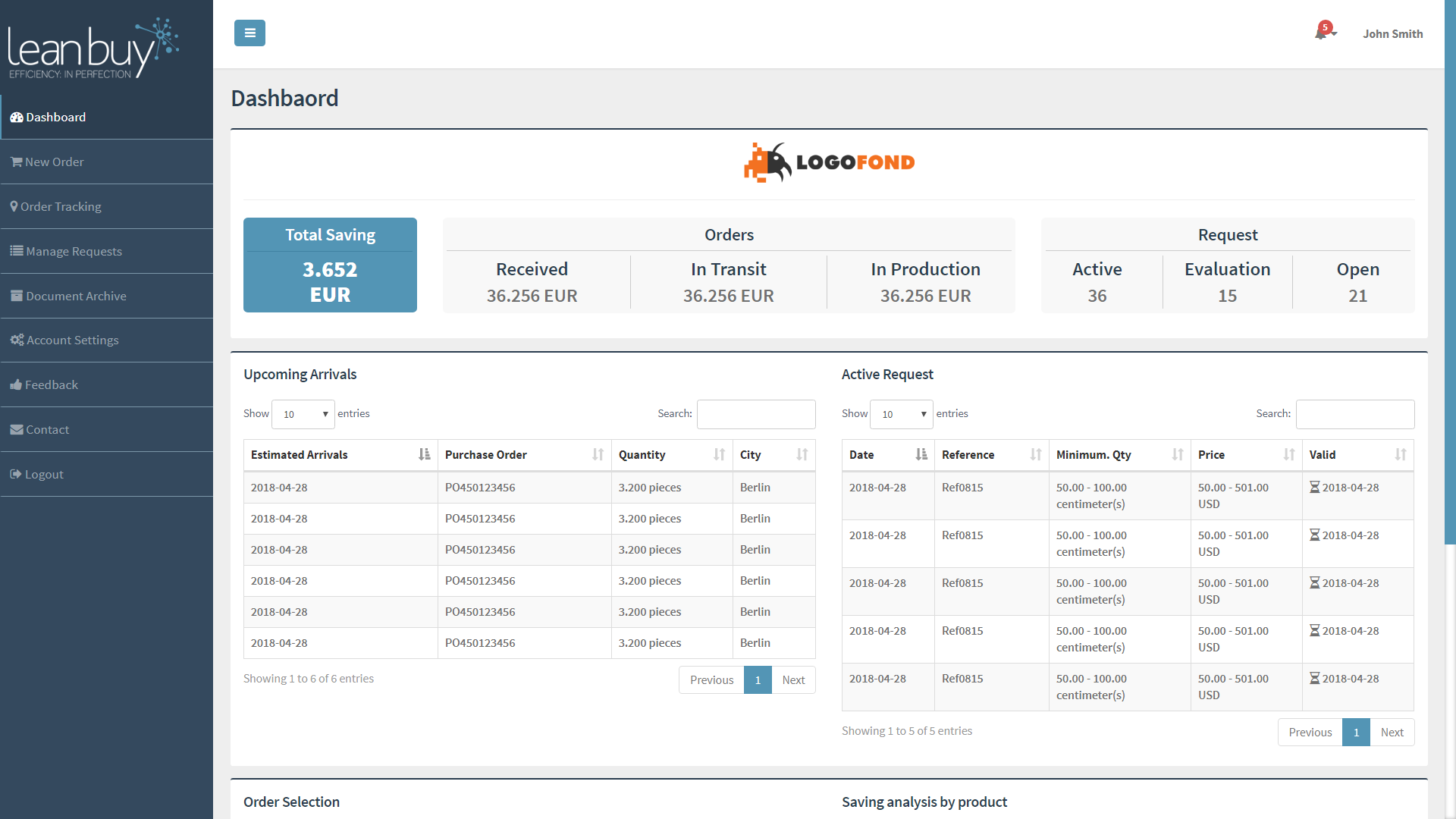

Read MoreDashboard

The supply chain dashboard informs the client in a comprehensive manner and at a glance about the status of all his inquiries and orders. It follows the progression of all transactions and outlines the next upcoming arrivals whilst providing insight into the financial savings being generated by switching procurement to lean buy.

Read Morelean buy specializes in three strategic product categories which support our client’s entire value chain, namely production materials, supportive consumables and promotional items.

Materials

lean buy’s material supply obtains the client-specific needs from profound technical analyses by our pre-sales-engineers. While some clients require high-quality machinery parts, others may be in demand for low-priced disposables. Depending on the respective customer’s strategy, we identify adequate procurement strategies for both cost and innovative quality leaders. By considering quality, lead time and costs whilst engineering our unique supply chains, we form the perfect match to our client’s success factors.

Consumables

Consumables such as pallets, packaging or other wearing parts are mostly cost-driven products and are best supplied in bigger quantities to achieve maximum fixed cost degression. We are well acquainted with all the hacks and tricks used to keep logistics costs at a minimum. Right from planning consolidated production all the way up to the intelligent balancing of container shipments with counter density freights, lean buy knows how to always stay one step ahead of the competition.

Promotional items

We play to our strengths when it comes to promotional items, which can range from promo t-shirts to promotional pens. The voluminous and light-weighted promotional items are an efficient counter freight to our high density wearing and machinery parts, which reduces the freight costs allocated to both commodity types by utilizing our load unit’s logistics capacity to the maximum. On top of our efficient logistics, our direct relationships to leading large-scale manufacturers in the Far East allow for the best prices on the market.

Professional supply chain management relies on a well-established partner network

PARTNERS ON SIX CONTINENTS

lean buy continuously works on developing its globally unique partner network to fulfil all sorts of sourcing requests for its clients. We are proud of having established reliable and long-lasting business relationships on six continents with best-in-class contract manufacturers, logistics partners and local agents which under lean buy’s coordination all contribute to the successful establishment of global, value-driven supply chains.

DYNAMIC PARTNER NETWORK

Every client inquiry leads our supply chain engineers to weave a temporary net of highly specialized partners from our dynamic partner network of manufacturers, logistics providers and financing partners with the common aim in mind of building the best adapted and most efficient supply chain solution for our client’s specific demand.

SCORING DATABASE

Selecting the right partners to cater for the specific needs of our unique clients is not left to chance, but comes as the result of a comparative assessment of the client's specific requirements versus what our partner database has to offer. Our well-maintained scoring model supports our supply chain engineers with empirically profound analyses when selecting the most suitable partners for each and every supply chain inquiry.

AGILITY

At lean buy we aim to establish a reliable but above all dynamic partner network which caters to the need for a high degree of flexibility and agility. We firmly believe in agility and adaptability as the best answer to our fast changing, globalized world with all its uncertainties and trade risks. Our constantly developing partner network builds the perfect base for dynamically scaling up or diversifying your business, whilst, at the same time, protecting it from adverse impacts from unforeseen market or technology changes. We firmly believe in the survival of the fittest, which has always been the most adaptable business.